Engineers have introduced a surprisingly simple construction material that could disrupt the $500 billion global building industry — and it’s made from everyday ingredients few would expect.

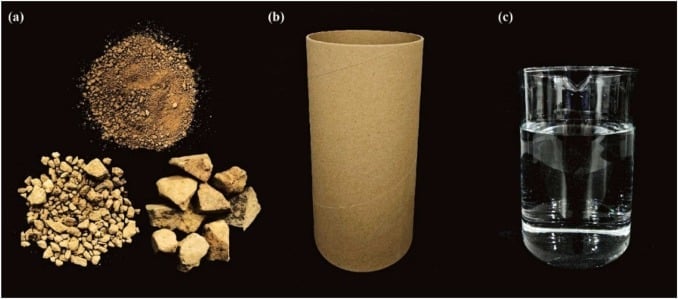

Inside a laboratory in Melbourne, a team of researchers may have set the stage for a major transformation in construction practices. Scientists at RMIT University have created a building material composed solely of soil, water, and recycled cardboard — eliminating the need for cement entirely. Intended for low-rise structures, the material is strong, widely accessible, and dramatically cleaner than traditional concrete.

Cement — the critical binder in concrete — is responsible for nearly 8% of global carbon dioxide emissions, according to data referenced by the U.S. Environmental Protection Agency. Although numerous alternatives have been proposed over the years, none have managed to combine affordability, practicality, and sustainability as effectively as this innovation.

Concrete’s Carbon Problem Meets a Stripped-Down Alternative

The newly developed material, named cardboard-confined rammed earth (CCRE), merges compacted soil with recycled cardboard tubes to form a simple yet durable wall system. Early findings indicate this method produces only one-quarter of the carbon emissions of concrete — at less than one-third of the production cost.

Traditional rammed earth construction has been used for centuries and involves compressing damp soil to form solid walls. In modern versions, cement is usually added to increase strength, which cancels out many of the environmental benefits.

“Modern rammed earth construction compacts soil with added cement for strength. Cement use is excessive given the natural thickness of rammed earth walls,” explained Dr. Jiaming Ma, the study’s lead author, in an interview published by ScienceDaily.

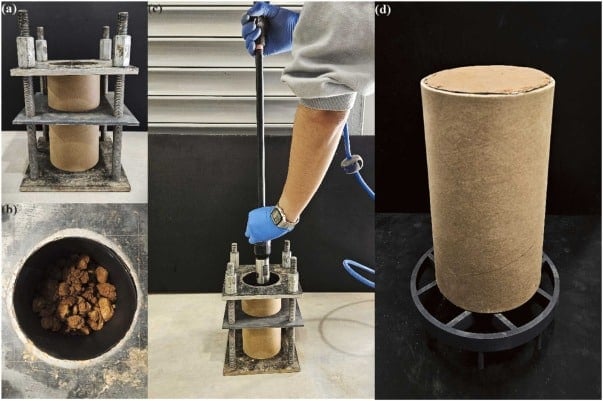

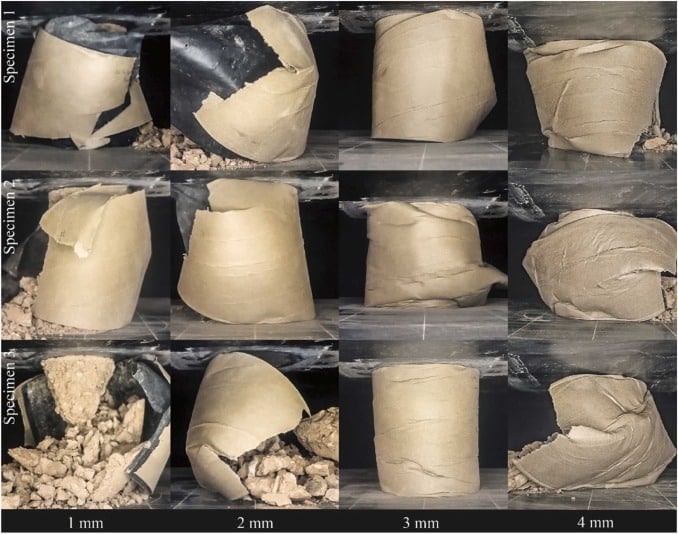

By encasing compacted soil in cylindrical cardboard molds, the team discovered they could maintain structural integrity without using any cement. This approach prevents cracking, supports vertical loads, and eliminates the need for emission-heavy industrial materials. Even more, the system is fully recyclable — meaning construction waste can be drastically reduced.

Australia discards over 2.2 million tons of paper and cardboard each year. Redirecting even a portion of that waste toward CCRE construction could deliver notable environmental and economic advantages. The full technical report appears in Case Studies in Construction Materials, a peer-reviewed journal.

Site-Made, Lightweight, and Ready for Deployment

According to the RMIT team, CCRE can be manufactured directly on construction sites. Builders simply compress a soil-and-water mixture inside recycled cardboard tubes. The process can be carried out manually or with low-power machinery, removing the need for large factories or heavy transportation.

“Instead of hauling in tonnes of bricks, steel and concrete, builders would only need to bring lightweight cardboard, as nearly all material can be obtained on site,” said Emeritus Professor Yi Min ‘Mike’ Xie, a corresponding author of the study, as quoted in ScienceDaily.

This streamlined approach makes CCRE especially attractive in rural or resource-limited areas. It aligns with global efforts to promote localized, low-carbon construction — particularly in countries facing housing shortages intensified by climate pressures.

CCRE’s natural thermal mass also adds to its appeal in warm regions. Rammed earth structures help regulate temperature and humidity, lowering reliance on mechanical cooling systems. As Dr. Ma noted, “Rammed earth buildings are ideal in hot climates because their high thermal mass naturally regulates indoor temperatures and humidity, reducing the need for mechanical cooling and cutting carbon emissions.”

The strength of the final structure depends on the thickness of the cardboard cylinders, a factor the researchers have already modeled. This allows builders to customize the system for different load requirements. For enhanced performance, the team has also explored reinforcing the soil mixture with carbon fiber — achieving strength levels comparable to advanced concrete blends.

A Real-World Pivot Point for Construction

The potential applications of CCRE extend far beyond its simple ingredients. According to RMIT’s research repository, the team is now seeking industry partners to test the material in real-world projects. With global pressure to reduce emissions from the building sector, governments and developers are increasingly seeking practical, low-carbon alternatives.

Unlike many emerging sustainable materials, CCRE appears immediately scalable. It does not rely on rare raw materials, specialized technology, or energy-intensive production lines. Its essential components — soil, water, and waste cardboard — are widely available around the world. That accessibility may be one of its most powerful advantages.

The research also complements broader trends in nature-based building technologies, such as hempcrete and mycelium-based composites. Although these materials have gained attention for their eco-friendly properties, CCRE distinguishes itself through its simplicity and on-site practicality. It can be mixed, molded, and constructed with minimal resources.